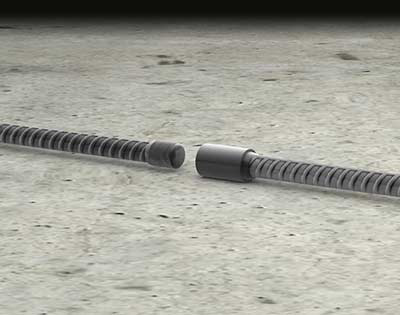

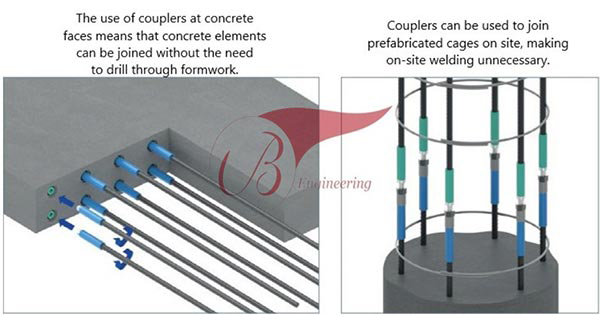

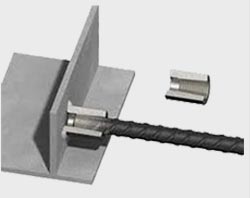

Rebar couplers replace standard rebar lap joints in reinforced-concrete structures. They are also suitable for reinforced-concrete columns and walls. Each rebar coupler consists of a piece of rebar with a threaded end and a coupler sleeve installed on the right side during installation.

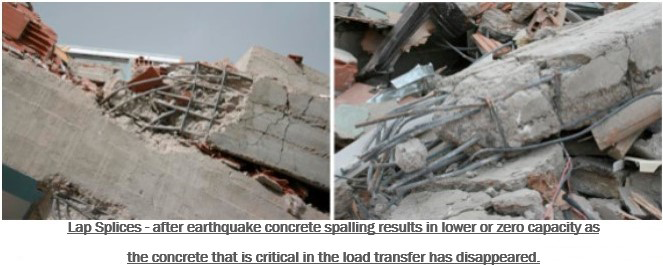

Rebar couplers can replace all rebar passing through formwork at construction joints. Historically, lap splicing has been the primary method of load transfer between reinforcement bars.

Self drilling anchors combine drilling, grouting, and anchoring in one process. They are fully threaded hollow steel tubes with specified inner and outer diameters.

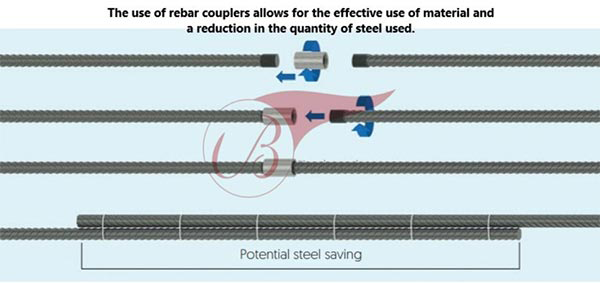

Traditional lapping of reinforcement is not always ideal. Mechanical rebar couplers provide stronger, more convenient, and often safer connections.

JB Rebar Couplers join rebars with full tension capacity using threaded ends and a coupler sleeve that transfers force across the joint.

When you choose JB-9 Rebar Couplers - Bar Lock from JB Engineering Corporation / Rebar Couplers India Pvt. Ltd., you benefit from a mechanical splicing system designed for modern reinforced-concrete construction. These couplers deliver full tension capacity and continuous reinforcement without being dependent on concrete bond alone.

In summary, JB-9 Rebar Couplers provide a reliable, efficient and structurally superior alternative to traditional lap splicing, especially in projects where quality, safety and speed matter.

The JB-9 Rebar Couplers (Bar Lock) act as mechanical splices that directly transmit load from one bar to another, independent of concrete bond or strength.

JB Engineering manufactures rebar couplers ensuring continuity, reduced congestion, and steel savings up to 25%. Certified bar-break couplers maintain ductility even under seismic load. JB Rock Bolts are among the largest manufacturers and exporters of Self Drilling Anchor Bolt Systems in India.

JB Engineers offers Self Drilling Anchors in R25, R32, R38, R51, and T76 variants with accessories such as nuts, plates, couplers, and drill bits.

Weldable couplers connect rebar to structural steel sections or plates. One end is internally taper-threaded, and the other end prepared for welding.

Steel Rebar Couplers join two steel bars using a threaded sleeve, ensuring robust mechanical connection in concrete structures.

Tapered Thread Rebar Couplers are fitted to threaded bar ends and tightened on site using a calibrated torque wrench.

MBT Rebar Couplers need no bar end preparation. Lock-shear bolts embed into the bar to form a secure mechanical grip.