The Self-Drilling Anchor Bolts System is comprised of a hollow threaded bar with an attached drill bit that can perform drilling, anchoring and grouting in a single operation. The hollow bar allows air and water to freely pass through the bar during drilling to remove debris and then allow grout to be injected immediately after drilling is completed.

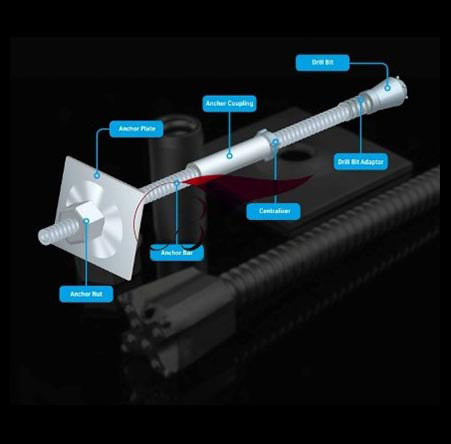

Self drilling anchor bolts is composed of hollow anchor bar, coupler, nut, drill bit, plate, and centralizer. It can combine drilling, grouting and anchoring in one process. Self drilling anchors are the advanced type of fully threaded hollow steel tube rods. SDA is a fully threaded rod with an inner and outer diameter hollow steel tube.

It is provided with a sacrificial drill bit at the end to facilitate the drilling process, coupler to join two SDA bars, screw nut, base plate, etc.

The hollow bar allows air and water to freely pass through the bar during drilling to remove debris and then allow grout to be injected immediately after drilling is completed. Grout fills the hollow bar and completely covers the entire bolt. Couplers can be used to join hollow bars and extend the bolt length while nuts and plates are used to provide the required tension.

Grout fills the hollow bar and completely covers the entire bolt. Couplers can be used to join hollow bars and extend the bolt length while nuts and plates are used to provide the required tension. Jb Rock Bolts are the largest manufacturers, suppliers and exporters of all types of Self Drilling Anchor Bolt System in India.

JB Engineers Offers Self Drilling Anchors in variants of R25, R32, R38, R51 and T76 and their accessories including the Anchor Nut, Anchor Plate, Anchor Couplers and Drilling bits.

Self drilling anchor bars are a perfect solution to small diameter drilling needs. They come in 3 meter segments that can easily be expanded with the use of couplers. The entire bar is threaded uniformly meaning it can be cut to size to fit any particular application. Various drill bits are configured to fit the thread allowing for a variety of different applications.

Self-drilling anchor(SDA) combines drilling, insertion and grouting into one easy operation. It reduces project lead time and installation difficulty. JB Engineers utilizes low carbon steel in all of its anchor production. Low carbon content in steel increases its ductility, reduces its brittleness, and resists corrosion cracking and carbon embrittlement. This choice of material significantly reduces occurrences where rockbolt may snap or buckle during onsite installation.

Rock bolts, which are commonly assigned the general term ”rock bolts”, are used for rock reinforcement in Mining and Tunneling. Rock bolts limit the loosening of blocks out of the rock mass and shear displacements. Furthermore, the frictional force between individual rock layers is increased.

The SN-Bolts are used for mining, tunnelling and specialized civil engineering. The securing in a borehole is made by the mortar fill process where mortar is first added to the borehole, starting from the deepest level of the bore hole and then the anchor is driven into the fresh mortar.