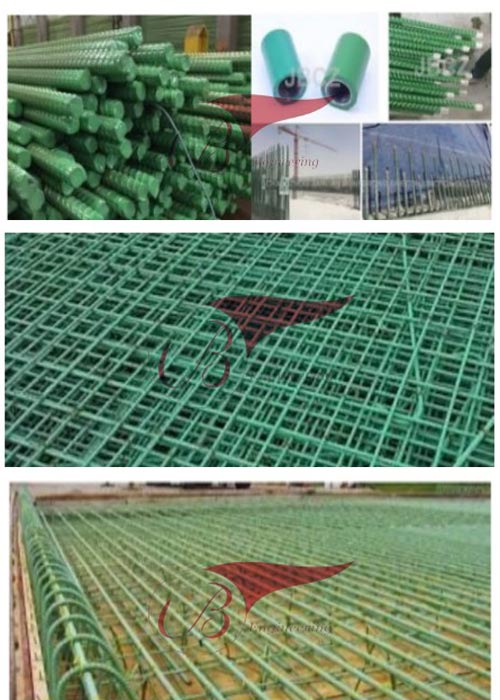

JB Engineering Zinc Coated /Epoxy Coated TMT Bars are highly corrosion resistant variant of steel bars which are protected by Fusion Bonded Epoxy coating. Fusion Bonded Epoxy coating, commonly used to protect concrete TMT bars, steel pipes, piping connections etc. used in construction. Fusion Bonded Epoxy coatings are in the form of dry powder at normal atmospheric temperature. The powder is applied electrostatically to the surface of cleaned steel bars and cured to form a protective film after undergoing various chemical processes. The epoxy coated bars last longer due to the protective Application and contribute to the quality of construction.

JB Engineering Fusion Epoxy Coated TMT Bars are available in grades 500D/550D/600D/670/800/950/1050 Mpa & sizes from 6mm to 50mm.

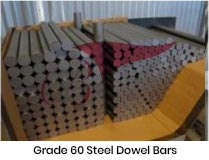

JB Engineering Rock Bolts is a leading manufacturer and exporter of Steel Dowel Bars that are being designed as per the national and international standard quality of raw materials. These ASTM A615 Grade 60 Steel Dowel Bars are used to carry out the transmission of load from one block to another, at the same time letting the axial thermal development alongside with the axis of dowel. These BS 4449 Epoxy Coated Dowel Bars are by and large made from plain round material, where they offer a hard-wearing and corrosion resisting elucidation to connections in tangible or other operational applications.

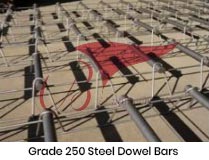

SDA Bar In India is a bolting solution for different ground conditions including sand, gravel, silt, and clays, and in soft to medium fractured rock formations. Our drill bits are available in different designs and diameters and thread types. Our SDA Bar's are compatible with most standard rock drilling equipment.

Self-drilling anchors are the advanced type of fully threaded hollow steel tube rods. SDA is a fully threaded rod with an inner and outer diameter hollow steel tube. It is provided with a sacrificial drill bit at the end to facilitate the drilling process, coupler to join two SDA bars, screw nut, base plate, etc. The hollow steel tube has one side sacrificial drill bit and, at another end, tied with nut and steel base plate. A hollow steel tube is placed in the center of the drill hole using a centralizer to maintain its position. The grout, which covers the SDA periphery, protects the SDA Rod under aggressive environment conditions with simultaneous grout ground and grout bar interaction throughout the threaded bond length. Self-drilling sacrificial drill varies based on the rock or soil conditions.

With our immense expertize in this particular domain we are involved in trading wholesaling and supplying a commendable range of Hollow Rod.

Self-Drilling Anchors are very suitable for weathered or un-consolidated rock stabilization. This technique is a more superior form of stabilization because the SDA technique is a relatively easy and fast method of installation compared to the outdated methods.

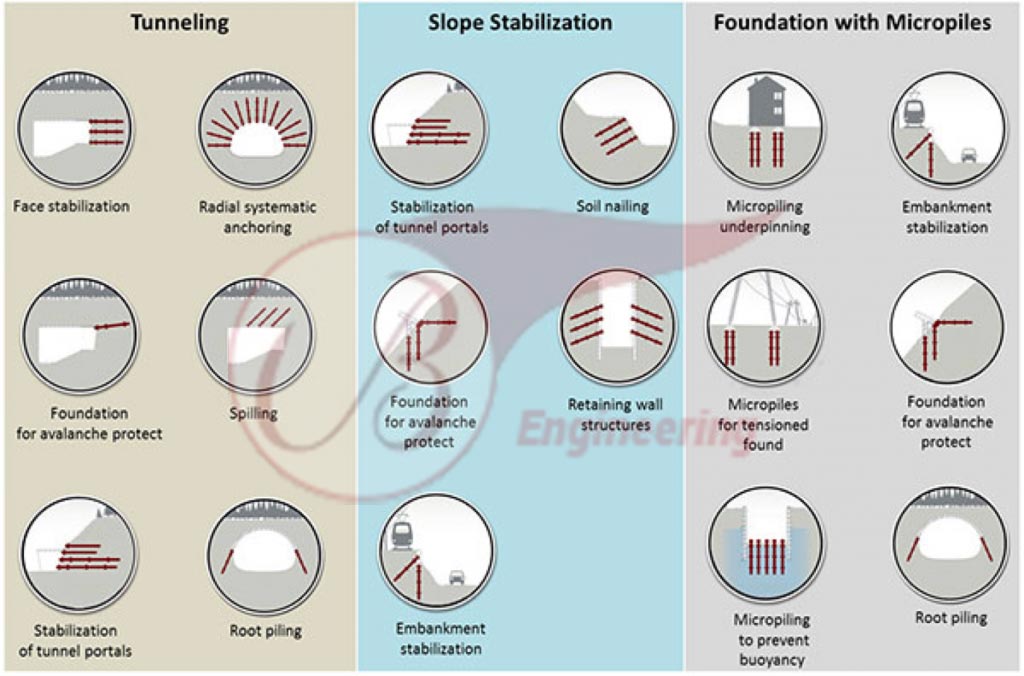

SDA Bar can be used like monopoles and micropile types because these are drilled piles composed of steel reinforcement with injected grout. These anchors are used like micropile type to stabilize the ground and related foundation problems. These anchors are suitable for tension and compression loads at varying ground conditions.

Self-drilling anchors bolts in India are most suitable for the stabilization of tunnel strengthening works. Mostly for the soft rock and overburden soil conditions, the SDAs are apt for rooftop protection.

JB Engineering Rock Bolts holds vast experience in this domain and is involved in manufacturing of a wide assortment of Full Threaded Hot Rolled Bars & Tie Rods. These Bars are used for anchor systems used for tunnels, transmission lines and antennas, excavation shoring, retaining walls, dam tie-downs and buried structures; turbine tower anchor bolts systems etc.

Our Hot Rolled Threaded Bar offered can be made available by us in different finish sizes. Hot Rolled Threaded Roads are long rods with continuous threading entire its length.

Manufactured from corrosion resistant Stainless Steel, they are available in a wide range of diameters, lengths, and surface finishes. They are engineered ruggedly to resist stress and abrasion and are unaffected when in contact with harsh chemicals, solvents, acids, dyes, and sterilizing solution. These threaded tie rods & bars features corrosion resistance, high-temperature strength, scaling resistance, and low-temperature toughness.

Construction Building Hot Sale 10mm 12mm Concrete Iron Rod Price HRB400 Rebar Steel Rebar Steel Grade 60 Tie Rods Rebar

Cold/Hot Rolled Scaffolding Threaded Formwork Steel Concrete Tie Rod 16mm

15/17mm Hot Rolled Formwork Tie Rod With 190KN Breaking Load

Construction Building Hot Sale 10mm 12mm Concrete Iron Rod Price Hrb400 Rebar Steel Rebar Steel Grade 60 Tie Rods Rebar

Formwork Bolt Nut Tie Rod Wing Nut Cold Rolled Adjustable Golden Zinc Tie Rod For Building

Wire Coils Rod Hot Rolled Stainless Galvanized Steel Drawn Wire Free Cutting Steel SAE 1006 SAE1008 Q195 Q235 Construction