JB Engineering manufactures Scaffolding & Form work materials at our factory in Dist.-Una, Himachal Pradesh, INDIA by making use of sophisticated machinery and procedures to ensure that all our products meet the required specifications as determined by the Clients.

We pride ourselves in custom designed products for our clients.

JB Engineering never compromise on safety and quality and guarantees that:

A tunnel support system uses components like rock bolts, steel arches, shotcrete (sprayed concrete), and ground stabilization (grouting) to ensure tunnel stability by reinforcing surrounding rock/soil, preventing collapses, and managing water, often involving primary (immediate) and secondary (permanent) linings for safety and durability, adapting to various geological conditions.

The Quality Manual used by JB Engineering contains policies and guidelines relevant to the functions and operations which have an effect on the quality of the products, services & processes to ensure conformance to specified requirements. We follow the guidelines as per the quality standards set up by BIS 3696 -2 and International Quality Standards.

Jb-14 Steel Scaffolding Pipes (Pipes & fittings) is a core part of our business, we concentrate on producing high quality scaffolding pipes. Galvanized Pipes has long been one of the most used access materials in India. Scaffolding Pipes are galvanized to reduce rust and corrosion for a longer product life. Scaffolding Pipes also integrates into access scaffolding and is frequently used in power plants, refineries and petrochemical plant environments

Pipe Roofing System is a support system used in loose ground conditions in conventional and mechanized tunneling.

JB Engineering are manufacturer of high quality range of Concrete Batching Plant spares, Concrete Pump Spares ,transit Mixer Spares, Boom Placer Spares etc.

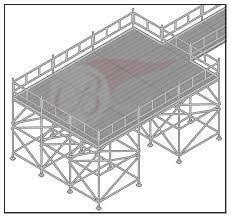

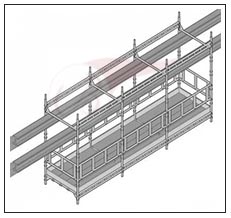

A Birdcage Scaffold is an independent scaffold that has more than two rows of standards in both directions that are connected by ledgers and transoms. It is mainly used for work carried out on a single level, for example ceilings. You should refer to its specifications when erecting and dismantling birdcage scaffolds made from modular scaffolding.

A Trestle Scaffold is assembled from prefabricated trestles, braces and accessories. Trestle scaffolds, for example A-frame and H-frame trestle scaffolds are commonly used by bricklayers, plasterers and painters and for general fit-out and finishing work. Trestle scaffolds generally do not require a licensed scaffolder to erect or dismantle.

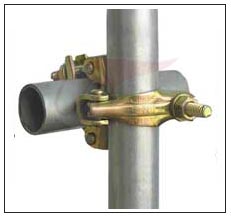

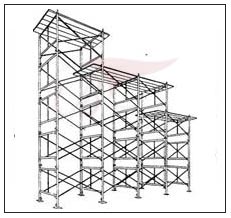

These are built from Pipeing and joining or fixing components (couplers) fixed together to form the required scaffold design. They are frequently used on structures with unusual designs, shapes or functions. The versatility of Pipes and coupler scaffolds means they can be assembled in a wide variety of different configurations. This also means erecting pipe and Rebar Coupler scaffolds can be complex when compared to prefabricated scaffolds.

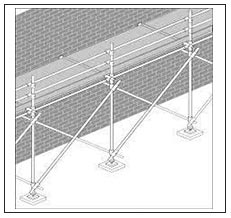

A Single Pole Scaffold consists of a single row of standards connected by ledgers. Putlogs are fixed to the ledgers and built into the wall of the building or structure. A Single Pole Scaffold is dependent on the structure against which it is placed for support. It is important that no components of this type of scaffold are removed until the scaffold is being dismantled.

A suspended scaffold incorporates a suspended platform capable of being raised or lowered when being used. An example of a suspended scaffold is a swing-stage scaffold.

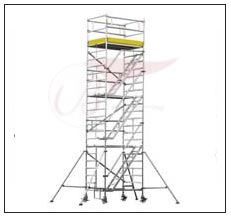

A tower scaffold is an independent scaffold that has four vertical standards connected longitudinally and transversely, or two frames in plan connected transversely to create a scaffold of one bay. A mobile scaffold is a tower scaffold mounted on wheels.

A Hung or Hanging Scaffold is an independent scaffold that hangs from another structure but can't be raised or lowered when in use.

This is defined as an integrated system of prefabricated components manufactured in such a way that the geometry of assembled scaffolds is pre-determined’. It can include modular, tower, cantilever, hung and suspended (swing-stage) scaffolds and must be design registered as required under Section 1 of Schedule 5 to the model WHS Act 2021 Regulations.