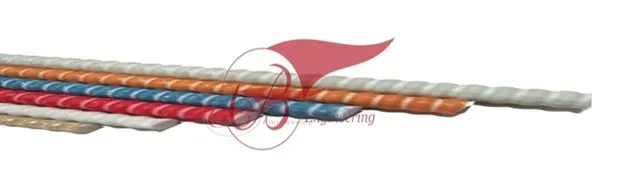

JB Engineering Glass Fiber Reinforced Polymer (GFRP) rebars available in 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 28mm, 32mm & 36mm; the tensile strength is twice stronger and four times lighter than TMT bars. These offers several advantages like corrosion resistance, stronger, lighter, cheaper are the important advantages of GFRP Rebars for Construction.

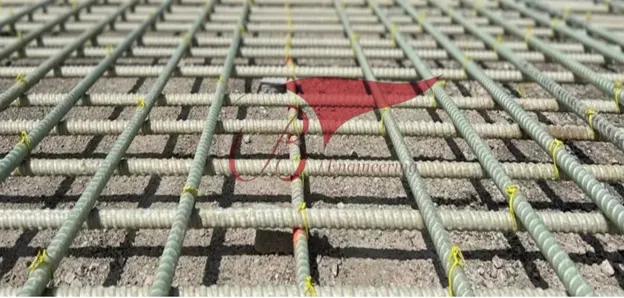

To overcome its low tensile capacity concrete structures are normally reinforced with steel reinforcement. The steel rebar is protected from corrosion by the alkaline environment in the concrete. This protection is normally satisfied when the structure is not subjected to an aggressive environment, has enough concrete cover, a limited number of cracking and good concrete qualities. However, over time carbonation, in particular if the structure is affected by chlorides from de-icing salts or seawater the reinforcement will start to corrode due to the reduction of alkalinity in the concrete. The Glass Fiber Reinforced Polymer survives for a long time period when its usage is made in around sea shore regions. It survives salty environment and protects itself for corrosion.

The use of externally bonded GFPR for retrofitting concrete structures is today commonly used and accepted worldwide. The use of internal reinforcement has not had the same rate of success, even though it is frequently used in around the world.

JB Engineering Glass Fiber Reinforced Polymer (GFRP) Rebars offers several Advantages for Construction which can contribute to cost savings, improved sustainability, and enhanced construction efficiency and can be narrated as under: